The Addie Beauty mission is to set a NEW worldwide standard of professional beauty tooling, whilst also raising awareness of the quietly understated, yet powerful industry that is the professional beauty industry. Addie Beauty also offers the best value for quality on all our Products. The most important and significant services that the company offers are best quality instruments for professionals, product customization, PRIVATE LABEL. Our staff offers the quickest and most flexible response to market demands.

Producing the Best European Quality under particularly resource-saving, sustainable conditions.

Addie Beauty has implemented ISO 9001:2015, an efficient quality management system compliant with international standards. Competent work cycle management is the key factor for manufacturing top notch products. Our company Addie Beauty has been certified by CE Declaration of Conformity, EU- MDR & FDA to offer instruments of unquestionable quality.

Producing the Best European Quality under particularly resource-saving, sustainable conditions.

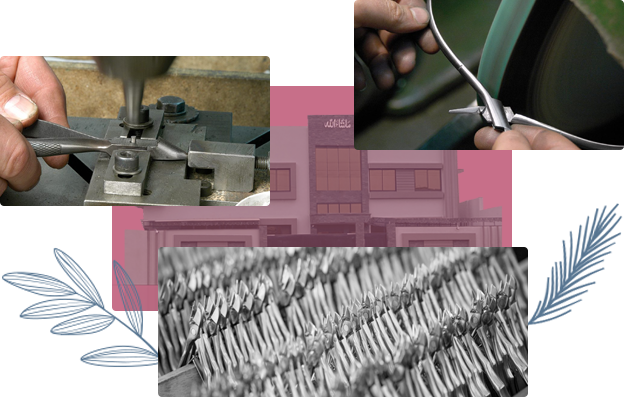

Each tool is handcrafted that preserve and promote craftsmanship. Addie Beauty tools are sharpened professionally by master craftsmen. Some processes require extra precision and meticulousness that machinery, no matter how sophisticated, cannot provide. That is why, for instance, all sharpening operations are exclusively manual. Due to specifics and peculiarities of the manicure instrument manufacturing we have introduced highly trained staff. We manufacture more than 22 000 000 production units annually, and every year our capacity is growing. Addie Beauty is the next generation technology meeting utter professionalism – the ultimate combination for making perfect tools.

Our instruments are produced with great care and passion with the aid of ultra-modern automation systems, robots, and highly experienced master craftsmen.

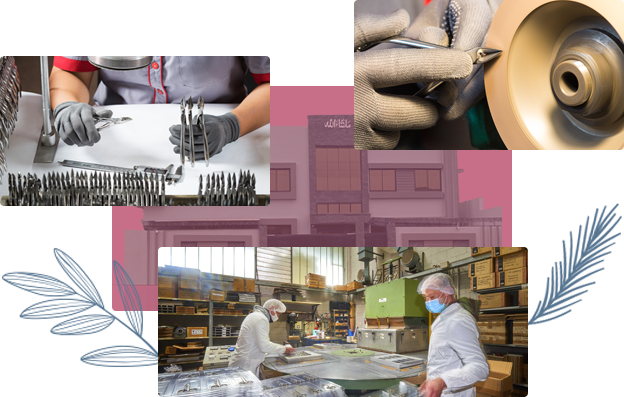

We at Addie Beauty dedicate ourselves to the product quality. Our production cycle includes input and output quality assurance processes. Quality of incoming raw materials is checked at the certified labs where physical and chemical aspects of steel are analyzed. Stainless medical grade steel imported from German is used for all instrument manufacturing. This sort of steel is exceptionally resistant to corrosion and has unmatched hardness, ensuring long-lasting sharpness. We use such steel for both professional and Eco ranges of our instrument.

Output quality assurance is performed by our QC department. QC specialists check all products for compliance with regulations and standards. We are constantly working on improving quality assurance procedures, so the QC department workers are periodically attending workshops and seminars by prominent beauty professionals to learn about peculiarities of use of various instruments. All that increases thoroughness of all tests and checks performed. If defects are found, the instrument is returned for rework. This meticulous approach guarantees that only high-quality products meeting all standards find their way to the market.

Each and every product is inspected separately and meticulously before leaving the production halls.